+86 15921716191

+86 15921716191

Leave Your Message

-

Contact WhatsApp

Contact WhatsApp -

Contact Phone

Contact Phone -

Contact Email

Contact Email

In the fast-paced world of business, the need for efficient labeling solutions is critical. International Barcode Label Printers play a vital role in inventory management and product identification. A reliable printer can streamline operations, saving both time and money. However, not all printers meet diverse business needs.

Choosing the right International Barcode Label Printers can be daunting. Each model offers different features, such as speed, print quality, and connectivity options. It’s essential to assess your specific requirements before making a purchase. Consider the printing volume and the type of labels used.

In 2026, some printers may excel while others fall short. The market is ever-changing, and what worked last year may not be effective now. Business owners must stay informed. Embracing innovation is key. Reflecting on past choices can lead to better decisions for the future.

When selecting international barcode label printers, several key features stand out. Print quality is crucial. A printer that delivers sharp, clear barcodes ensures easy scanning and enhances productivity. Look for printers with high DPI resolution options. This factor directly impacts the readability of your labels.

Consider connectivity options too. Modern printers offer Wi-Fi, Bluetooth, and USB capabilities. These features allow for flexibility in various work environments. It’s also important to assess the printer’s speed. A fast printer can handle high-volume tasks efficiently, saving time in busy operations.

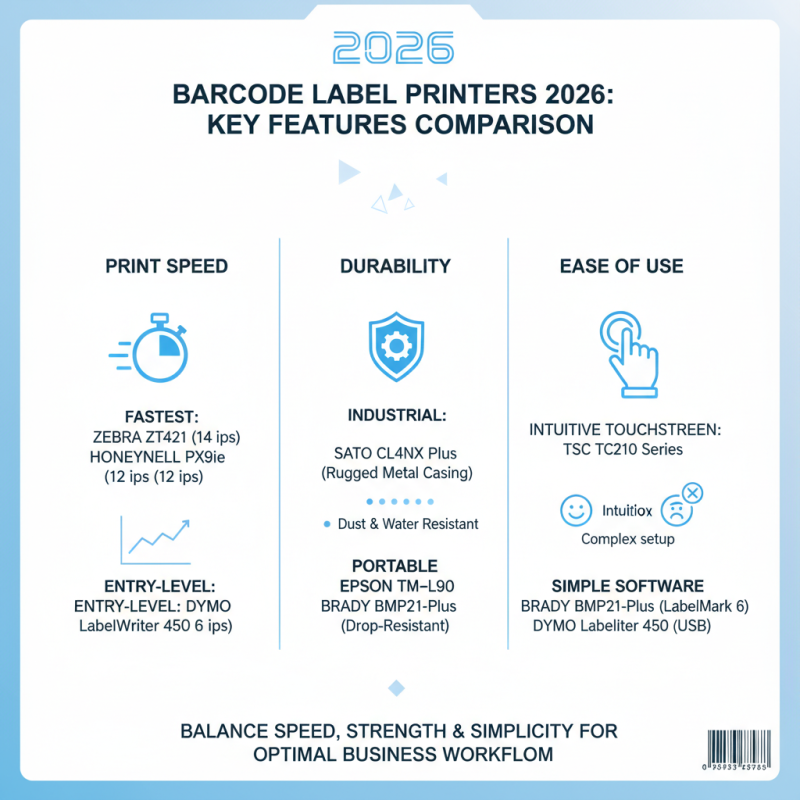

Another aspect is durability. Printers often face demanding conditions. Dust, spills, and temperature changes can affect performance. Investing in a robust machine can pay off in the long run. However, assess any additional maintenance requirements. Some printers may demand constant attention, which could be a hassle for businesses. These key features can significantly influence your choice in ensuring efficiency and reliability.

When selecting barcode label printers for your business in 2026, it’s essential to compare key features. Consider print speed, durability, and ease of use. Some printers excel in speed but might compromise on quality. Look for devices that balance both. Examine how user-friendly the interface is. Printers with complex setups can hinder your workflow.

Tips: Always review printer specifications carefully. A complicated machine might seem advanced but can frustrate staff. Test models when possible to understand real-world performance.

Another important aspect is connectivity options. Some printers offer wireless capabilities, making them versatile. However, ensure that they are compatible with your existing systems. Check if they can integrate with your inventory software smoothly. A well-integrated printer can save time and reduce errors.

Tips: Gather feedback from your team about their experiences with different models. Their insights can lead you to better choices. Monitor print quality consistently to avoid costly mistakes that come from poor barcodes.

Choosing the right barcode label printer for your business can be complex. Various factors affect this decision. Start by considering your specific needs. What materials will you be printing on? Can the printer handle these materials effectively? These questions matter.

Print speed is another key factor. If you need high volumes, a faster printer is crucial. However, faster printers often cost more. Weigh that against your budget. Some businesses may prioritize quality over speed. Low-volume printers can still produce clear, accurate labels.

Connectivity is essential too. Does the printer support wireless connections? This feature enhances flexibility in your workspace. Think about the software you will use. Compatibility with existing systems avoids future headaches. Mistakes can lead to costly delays. The right choice simplifies operations and improves efficiency. Careful consideration prevents issues down the line.

| Printer Model | Print Speed (mm/s) | Print Resolution (dpi) | Interface Types | Recommended Use |

|---|---|---|---|---|

| Model A | 100 | 300 | USB, Ethernet | Retail, Logistics |

| Model B | 150 | 600 | USB, Bluetooth | Manufacturing, Healthcare |

| Model C | 200 | 203 | USB, Wi-Fi | Warehouse, Distribution |

| Model D | 80 | 1200 | USB, Parallel | Office, Retail |

| Model E | 120 | 300 | USB, Ethernet, Bluetooth | Shipping, Warehousing |

Maintaining your barcode label printer is crucial for efficient operation. Regular cleaning is a must. Dust and debris can disrupt printing quality. A soft cloth and gentle cleaning solution can work wonders. Take time to wipe the print head and rollers. It’s a small effort that pays off in clear labels.

Check the ink and ribbon levels frequently. Running your printer on low ink can lead to faded labels. It’s frustrating to miss critical information due to poor print quality. Set reminders to check your supplies regularly. Sometimes, it’s easy to overlook this simple task.

Calibration is also important. An uncalibrated printer can cause alignment issues. Labels may print off-center or overlap. Follow the manufacturer’s guidelines for proper calibration. Don't hesitate to refer back to the manual when needed. A little patience can help prevent larger headaches in the future. Remember, maintaining your printer is an ongoing task. Regular checks can save time and frustration.

The future of barcode label printing technology is exciting. Advances in digital printing are creating more efficient and cost-effective solutions. Businesses will find more options to customize labels. Innovative materials and better inks are also emerging. Sustainability will play a vital role, as companies seek eco-friendly solutions.

Tips: Consider integrating smart technology. Using QR codes can enhance customer engagement. They lead to interactive experiences, making labels more than just identifiers.

Automation is another trend. Automated label applicators can speed up production. However, relying heavily on machines can overlook human skills. Training staff to understand both technology and design is crucial. Balancing automation with human insight is key.

Finally, track emerging technologies. Innovations like AR and NFC are changing how labels are used. Monitoring these trends can keep your business competitive. Yet, it’s essential to evaluate their application carefully. Not every trend may suit your needs.